In the world of metal fabrication, the importance of precision and durability cannot be overstated. Sheet metal flanges are more than just functional components they are essential elements that enhance strength, stability, and overall performance in assemblies. By focusing on durable flange designs, manufacturers can ensure long-lasting quality that meets both practical and aesthetic demands.

The Importance of Strong Flange Designs

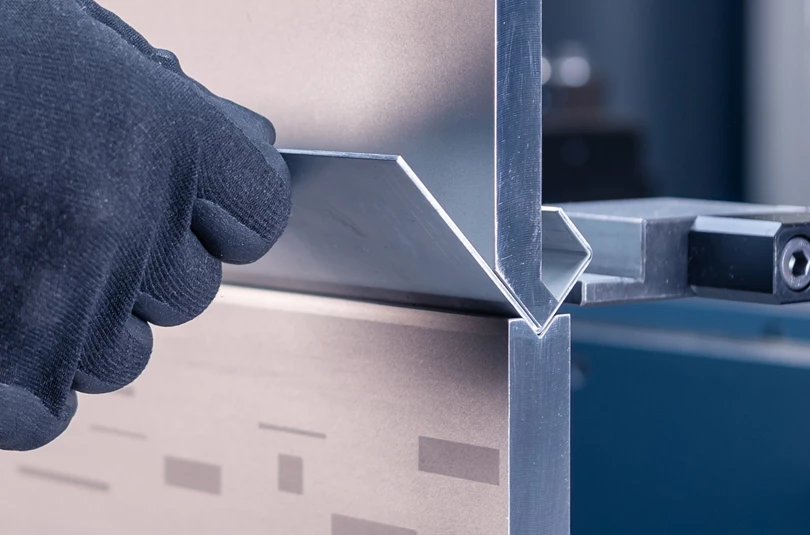

Sheet metal flanges serve as connectors, supports, and reinforcements in countless applications. Custom tools help create precise bends in each sheet metal flange efficiently. Durable flange designs help to:

- Improve structural integrity: A well-designed flange distributes stress evenly, preventing weak points and reducing the risk of deformation.

- Enhance longevity: High-quality materials and precise bends ensure that flanges withstand wear and environmental factors over time.

- Optimize assembly efficiency: Properly engineered flanges simplify installation, reduce errors, and enhance productivity in production processes.

By prioritizing these benefits, manufacturers can create components that perform consistently under demanding conditions.

Key Principles for Durable Flange Design

Achieving lasting quality starts with a careful approach to design. Key principles include:

- Material selection: Choosing corrosion-resistant metals like stainless steel or aluminum extends the lifespan of flanges.

- Precision in bending and shaping: Accurate bend radius and uniform edges prevent cracks and maintain the intended strength.

- Reinforcement strategies: Incorporating stiffening ribs or strategic folds improves load-bearing capacity without adding excessive weight.

Focusing on these factors ensures that each flange meets stringent performance standards while remaining cost-effective.

Benefits of Optimized Flange Performance

Investing in durable flange designs provides tangible advantages for both manufacturers and end-users:

- Reduced maintenance needs: Strong flanges resist wear, lowering repair frequency and associated costs.

- Consistent product quality: Reliable components contribute to the overall excellence of the finished product, enhancing brand reputation.

- Versatility across applications: From industrial machinery to HVAC systems, well-crafted flanges are adaptable to various uses without compromising quality.

These benefits highlight why attention to design details is critical for lasting success in metal fabrication. Engineers rely on software tools to determine the perfect sheet metal bend radius for complex designs.

Strategies to Maximize Durability

Enhancing the durability of sheet metal flanges requires both expertise and innovation. Effective strategies include:

- Advanced fabrication techniques: Employing laser cutting, CNC bending, and precision stamping ensures high accuracy.

- Quality control measures: Regular inspection and testing detect potential weaknesses before products leave the production line.

- Design customization: Tailoring flange dimensions and features to specific applications optimizes performance and reduces material waste.

By integrating these strategies, manufacturers can consistently deliver flanges that combine strength, efficiency, and aesthetic appeal.

Conclusion

Durable sheet metal flange designs are foundational to creating products that stand the test of time. Through thoughtful material selection, precise engineering, and proactive quality management, manufacturers can achieve flanges that offer superior strength, reliability, and versatility. Investing in quality design not only enhances performance but also fosters lasting value for clients and end-users alike. With optimized flange designs, every project becomes a testament to precision, durability, and excellence.